| 参数 | MIM | 传统PM | 机械加工 | 精密铸造 |

| 相对密度 |

98% |

98% |

100% |

98% |

|

拉伸强度 |

高 |

低 |

高 |

高 |

|

延 伸 率 |

高 |

低 |

高 |

高 |

|

硬 度 |

高 |

低 |

高 |

高 |

|

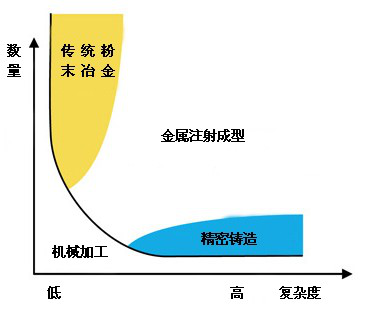

复杂程度 |

高 |

低 |

高 |

中 |

|

表面粗糙度 |

高 |

中 |

高 |

中 |

|

量产可行性 |

高 |

高 |

低 |

中 |

|

材料范围 |

高 |

高 |

高 |

中-高 |

|

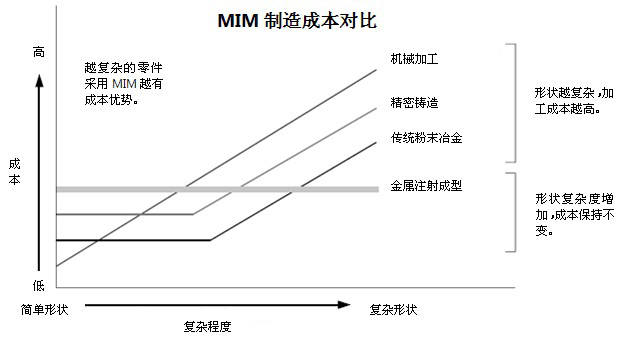

成 本 |

中 |

低 |

高 |

中 |

Comparison of MIM with traditional powder metallurgy

MIM can create complex shape products and avoid more two machining operations.

MIM the product has high density, good corrosion resistance, high strength and good ductility.

MIM can combine 2 or more PM products into a MIM product, saving materials and processes.

Comparison of MIM and machining

MIM design can save material and reduce weight.

MIM can repeatedly crush the injection material after injection, without affecting the product performance and high utilization rate of materials.

MIM forms complex products by molding at one time to avoid multiprocessing.

MIM can make complex shape parts that are difficult to machine.

Comparison of MIM and precision casting

MIM can make thin wall products, the thinnest can be 0.2mm.

The surface roughness of MIM products is better.

The MIM is more suitable for making thin blind holes and through holes.

MIM greatly reduced the workload of machining two times.

MIM can manufacture small parts quickly and in large quantities and at low cost.

常用MIM材料应用领域:

|

材料体系 |

合金牌号、成分 |

应用领域 |

|

低合金钢 |

Fe-2Ni, Fe-8Ni |

汽车、机械等行业的各种结构件 |

|

不锈钢 |

316L ,17-4PH |

医疗器械、钟表零件 |

|

硬质合金 |

WC-Co |

各种刀具、钟表、手表 |

|

钨合金 |

W-Ni-Fe, W-Ni-Cu, W-Cu |

军工业、通讯、日用品 |

|

钛合金 |

Ti,Ti-6Al-4V |

医疗、军工结构件 |

|

磁性材料 |

Fe,Fe14 Nd2 B,SmCo5 |

各种磁性能部件 |

几种典型MIM材料的性能:

|

|

材料 |

密度 |

硬度 |

拉伸强度 |

伸长率 |

|

g/cm3 |

洛氏 |

MPa |

% |

||

|

铁基合金 |

MIM-2200(烧结态) |

7.65 |

45HRB |

290 |

40 |

|

MIM-2700(烧结态) |

7.65 |

69HRB |

440 |

26 | |

|

MIM-4605(烧结态) |

7.62 |

62HRB |

415 | 15 | |

|

MIM-4605(淬、回火) |

7.62 |

48HRC |

1655 | 2 | |

|

不锈钢 |

MIM - 316L (烧结态) |

7.92 |

67HB |

520 | 50 |

|

MIM- 17-4PH (烧结态) |

7.5 |

27HRC |

900 | 6 | |

|

MIM- 17-4PH (热处理态) |

7.5 |

40HRC |

1185 | 6 | |

|

MIM - 430L (烧结态) |

7.5 |

65HRB |

415 | 25 | |

|

钨合金 |

95%W-Ni-Fe |

18.1 |

30 | 960 | 25 |

|

97%W-Ni-Fe |

18.5 |

33 | 940 | 15 | |

|

硬质合金 |

YG8X |

14.9 |

HRA90 |

弯曲强度 2300 |

|

|

精细陶瓷 |

Al2O3 |

3.98 |

HRA92 |

弯曲强度 530 |

|

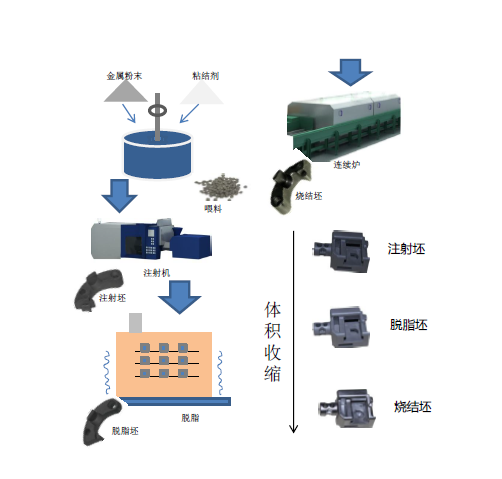

Compared with powder metallurgy, metal...

The development of powder co-injection...

Now with the development of economy, t...